Tstcheck Oil Test Kit Strips

Brand :TSTCHECK

Product origin :Changchun, Jilin, CN

Delivery time :3-20 days

Supply capacity :300,000 bottles

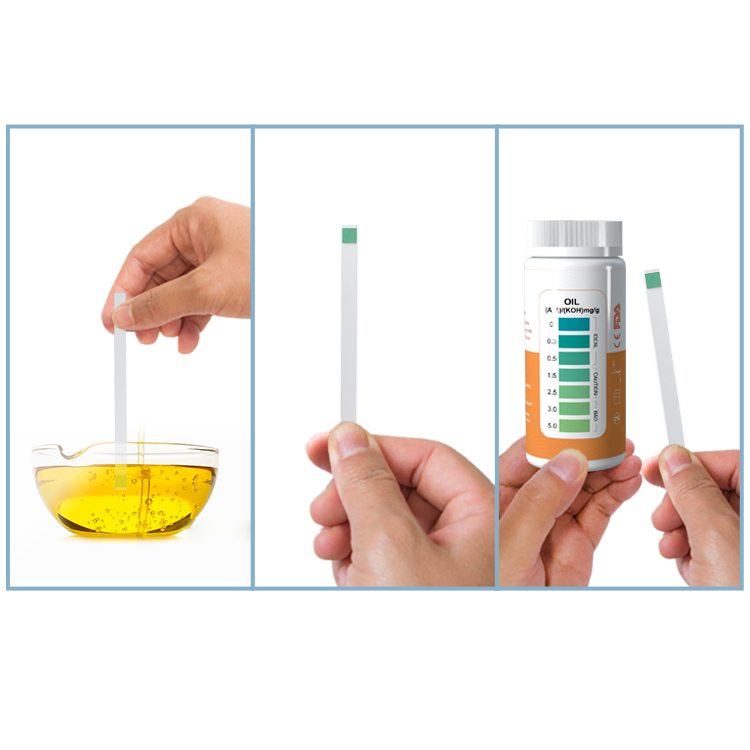

As rapid and affordable test products, Tstcheck Oil Test Kit Strips adopt new chromogenic agents and use highly sensitive chromogenic reaction activators to perform semi-quantitative analysis of water parameters.

The advantage of this oil test strips product is : Quick and easy test in 2 minutes optimizes oil consumption HACCP safety . Very easy to use and can get testing results in shorter time .

Jilin Test welcome to build success and long terms business cooperation with you in the near further .

Introduction to Oil Test Strips

1. The Significance of Monitoring Cooking Oil Quality

2. Understanding Oil Test Kit Strips

2.1 Components and Design

Reagent - Impregnated Zones: The test strips have multiple reagent - impregnated zones. Each zone is dedicated to detecting a particular aspect of oil quality. For example, one zone may be designed to detect the presence of free fatty acids, another for polar compounds, and yet another for oxidation products. These zones are clearly marked on the strip for easy identification during the testing process.

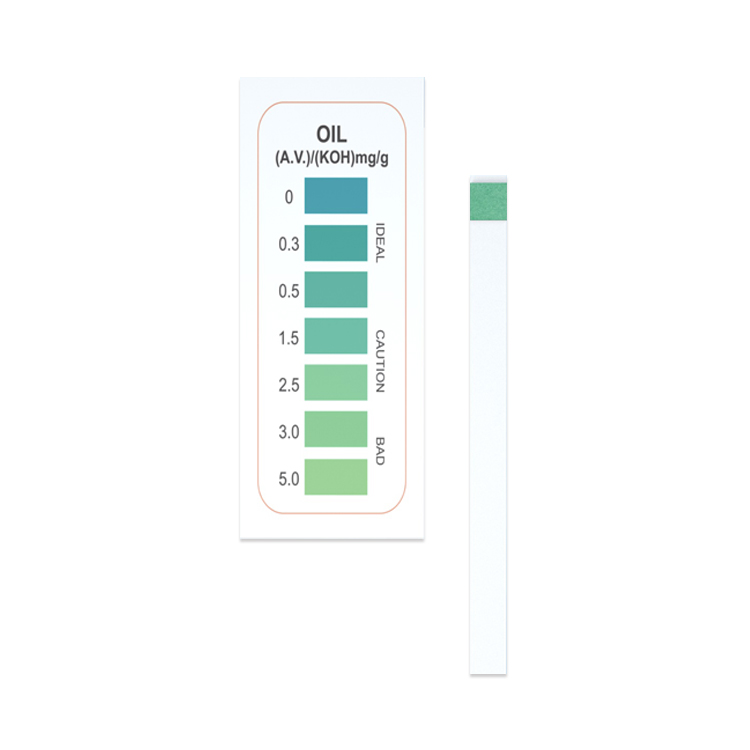

Indicator System: The reagents in the test strip zones are formulated to produce a visible color change when they react with the relevant substances in the cooking oil. The color change acts as an indicator of the oil's quality. The intensity of the color change is proportional to the concentration of the substance being detected. For instance, a darker color in the zone detecting free fatty acids indicates a higher concentration of these acids in the oil, which is a sign of oil degradation.

2.2 How Oil Test Strips Work

Reaction with Free Fatty Acids: Free fatty acids are produced as cooking oil breaks down. The reagent in the corresponding zone of the test strip reacts with these free fatty acids. This reaction often involves an acid - base reaction or a complex - formation reaction, depending on the type of reagent used. The result is a color change that can be easily observed.

Detection of Polar Compounds: As cooking oil deteriorates, the formation of polar compounds increases. These compounds are more polar in nature compared to the original oil molecules. The test strip has a reagent zone that specifically reacts with these polar compounds. The reaction may involve the binding of the polar compounds to the reagent, which causes a change in the electronic structure of the reagent and results in a visible color shift.

Response to Oxidation Products: Oxidation is a common process that cooking oil undergoes, especially when exposed to heat and air. Oxidation products such as peroxides and aldehydes can be detected by the test strip. The reagents in the relevant zones react with these oxidation products, and the subsequent color change indicates the extent of oxidation in the oil.

3. Types of Oil Test Kit Strips

3.1 General - Purpose Test Strips

Multi - Parameter Detection: With their ability to detect multiple parameters, general - purpose test strips save time and effort. Instead of having to use separate tests for each aspect of oil quality, a single strip can provide comprehensive information. This makes them convenient for those who need to regularly check the quality of their cooking oil but do not require highly specialized or in - depth analysis.

3.2 Specialized Test Strips

Frying Oil - Specific Test Strips: Frying oil is subjected to high temperatures and repeated use, which accelerates its degradation. Specialized test strips for frying oil are designed to be more sensitive to the specific changes that occur in frying oil. They may have enhanced reagents for detecting the formation of acrylamide precursors, which are of particular concern in fried foods. These test strips can help commercial fryers, such as those in fast - food restaurants, to monitor the quality of their frying oil more closely and ensure the safety and quality of their fried products.

Nut Oil or Specialty Oil Test Strips: Different types of oils, such as nut oils (e.g., almond oil, walnut oil) or specialty oils (e.g., truffle oil), have unique characteristics. Test strips designed specifically for these oils take into account their distinct chemical compositions. For example, nut oils may be more prone to rancidity due to their high unsaturated fat content. The test strips for nut oils are formulated to detect early signs of rancidity, such as the presence of volatile compounds produced during the oxidation of unsaturated fats.

4. Applications of Oil Test Kit Strips

4.1 Household Use

Ensuring Food Quality: In households, oil test kit strips are a valuable tool for home cooks. By regularly testing the cooking oil, they can ensure that the oil used in their recipes is of good quality. This not only enhances the taste and texture of the food but also contributes to the overall nutritional value. For example, using fresh, high - quality oil in baking can result in a more flavorful and moist product, while degraded oil may impart off - flavors.

Health Considerations: Degraded cooking oil can contain harmful substances such as free radicals and oxidized lipids, which are associated with various health problems, including inflammation and an increased risk of chronic diseases. By using test strips to monitor the oil quality, households can avoid consuming oil that may be detrimental to their health.

4.2 Food - Service Industry

Restaurant and Café Operations: Restaurants and cafes use large quantities of cooking oil on a daily basis. Oil test kit strips are essential for maintaining the quality of the food they serve. By regularly testing the oil, they can determine when to change the oil in their fryers or when the oil used in other cooking processes has become too degraded to use. This helps in reducing waste, as oil that is still in good condition can be continued to be used, while preventing the use of oil that may affect the taste and safety of the food.

Food Manufacturing: In food manufacturing plants, where cooking oil is used in large - scale production processes, oil test kit strips play a crucial role in quality control. Whether it's in the production of snacks, baked goods, or processed foods, the quality of the cooking oil can impact the final product. Test strips are used to ensure that the oil meets the required quality standards at every stage of the production process, from the initial oil storage to the actual cooking or frying step.

4.3 Culinary Education and Training

Cooking Schools and Institutes: In cooking schools and culinary training institutes, students need to learn about the importance of using high - quality cooking oil. Oil test kit strips are used as teaching tools to demonstrate how to assess the quality of oil. Students can practice using the test strips to understand the signs of oil degradation and how different cooking methods and storage conditions can affect the oil's quality. This hands - on experience helps them develop the skills necessary to make informed decisions about oil usage in their future culinary careers.

5. Advantages of Using Oil Test Kit Strips

5.1 Simplicity and Ease of Use

5.2 Quick Results

5.3 Cost - Effectiveness

5.4 Portability

6. Comparing Oil Test Kit Strips with Other Oil Testing Methods

6.1 Laboratory - Based Analyses

Complexity and Cost: Laboratory - based oil analyses, such as gas chromatography - mass spectrometry (GC - MS) and high - performance liquid chromatography (HPLC), are highly accurate and can provide detailed information about the chemical composition of cooking oil. However, these methods are extremely complex and require expensive equipment, trained technicians, and a well - equipped laboratory. The cost of conducting such analyses is also high, both in terms of equipment investment and the cost of each individual test. In contrast, oil test kit strips offer a simple and cost - effective alternative for routine quality checks.

Time - Consuming: Laboratory - based analyses often take a significant amount of time. The sample preparation, instrument calibration, and actual analysis can take hours or even days to complete. This is not practical for situations where immediate results are needed, such as in a busy food - service environment. Oil test kit strips, on the other hand, can provide results within minutes.

6.2 Sensor - Based Oil Testers

Initial Investment: Sensor - based oil testers are another option for monitoring oil quality. These testers use sensors to detect changes in the electrical, optical, or other properties of the oil. While they can offer real - time monitoring in some cases, they often require a relatively high initial investment. The cost of purchasing the sensor - based tester, along with any associated software or accessories, can be prohibitive for many small - scale users. Oil test kit strips, with their low cost per test, are a more accessible option for those on a budget.

Limitations in Parameter Detection: Some sensor - based oil testers may be limited in the number of parameters they can detect. They may focus on one or two key aspects of oil quality, such as viscosity or conductivity, while oil test kit strips can often detect multiple parameters simultaneously, providing a more comprehensive assessment of the oil's condition.

7. Storage and Shelf - Life of Oil Test Kit Strips

7.1 Storage Conditions

7.2 Shelf - Life

8. Conclusion

Factory. We speicalize in producing water test strips for years....more

-

Download

- Category.pdf