Oil Test Kit

Brand :TSTCHECK

Product origin :Changchun, CN

Delivery time :3-20 days

Supply capacity :300,000 bottles

Oil Test Kit is developed and manufactured by Jilin Test Bio-Electron Co., Ltd. The testing products have been successful in the world market for many years.

Whether you are looking for a quick way to test your oil , or you want to make sure that your oil is free of dangerous, we have a product for you.

Our Oil Test Kit adopts new chromogenic agents and use highly sensitive chromogenic reaction activators to perform semi-quantitative analysis of water parameters. It is your best choice to choose our product to make your food safety.

Water Pollution Prevention: Oil contamination in water is a major environmental concern. Even a small amount of oil in water can have devastating effects on aquatic ecosystems. For example, oil spills in rivers or lakes can coat the feathers of waterfowl, impairing their ability to fly and stay warm, and can also suffocate fish by clogging their gills. Our oil test paper and strips play a crucial role in preventing such disasters. In industrial areas, where there is a risk of oil - containing wastewater being discharged into water bodies, regular testing using our products can detect even trace amounts of oil. This allows industries to take corrective measures before the contaminated water is released, protecting the environment and aquatic life.

Groundwater Monitoring: Groundwater is a vital source of drinking water for many communities. Oil - based chemicals, such as those from underground storage tanks or industrial activities, can seep into the groundwater. Our oil test strips can be used to monitor groundwater quality in areas near gas stations, factories, or other potential sources of oil contamination. By detecting oil in groundwater early, water treatment plants can implement appropriate measures to remove the contaminants, ensuring the safety of the drinking water supply.

Machinery Lubrication and Maintenance: In industries where machinery operates using water - based lubricants or coolants, the presence of oil can disrupt the lubrication process. For instance, in metal - cutting operations, water - soluble cutting fluids are used to cool and lubricate the cutting tools. If these fluids become contaminated with oil, it can lead to reduced tool life, poor surface finish of the machined parts, and increased energy consumption. Our rapid oil test strips enable operators to quickly check the quality of the lubricants and coolants. By regularly testing, maintenance teams can detect oil contamination early and take steps such as filtering or replacing the fluids, thereby optimizing machinery performance and reducing maintenance costs.

Process Control in Manufacturing: Many manufacturing processes involve the use of water - oil emulsions or require strict control over the oil content in water - based solutions. For example, in the textile industry, certain finishing processes use water - based solutions with specific amounts of oil - based additives. If the oil content deviates from the optimal level, it can affect the quality of the fabric, such as its softness, colorfastness, and durability. Our reliable quality oil test paper allows manufacturers to monitor the oil content in these solutions accurately. This ensures that the manufacturing process runs smoothly and the final products meet the required quality standards.

Food Safety and Quality: In the food and beverage industry, the presence of oil in water - based products or in the water used for processing can pose significant risks to food safety and quality. For example, in the production of bottled water, any oil contamination can introduce off - flavors and odors, making the product unpalatable. In addition, oil can provide a medium for the growth of microorganisms, increasing the risk of food - borne illnesses. Our oil test solutions can be used to test the water used in food processing plants, as well as the final products themselves. By ensuring that there is no oil contamination, food and beverage manufacturers can maintain the high - quality standards expected by consumers and comply with strict food safety regulations.

Reagent - Based Chemistry: Our oil test paper and strips are impregnated with specialized chemical reagents. These reagents are carefully selected to react specifically with different types of oils or oil - related compounds. For example, some reagents are designed to react with hydrocarbons, which are the main components of most oils. When the test paper or strip comes into contact with an oil - containing sample, a chemical reaction occurs. This reaction often involves oxidation or complex - formation processes. In the case of oxidation - based reactions, the reagent may be oxidized by the oil, resulting in a change in its chemical structure. This change is accompanied by a visible color change on the test paper or strip.

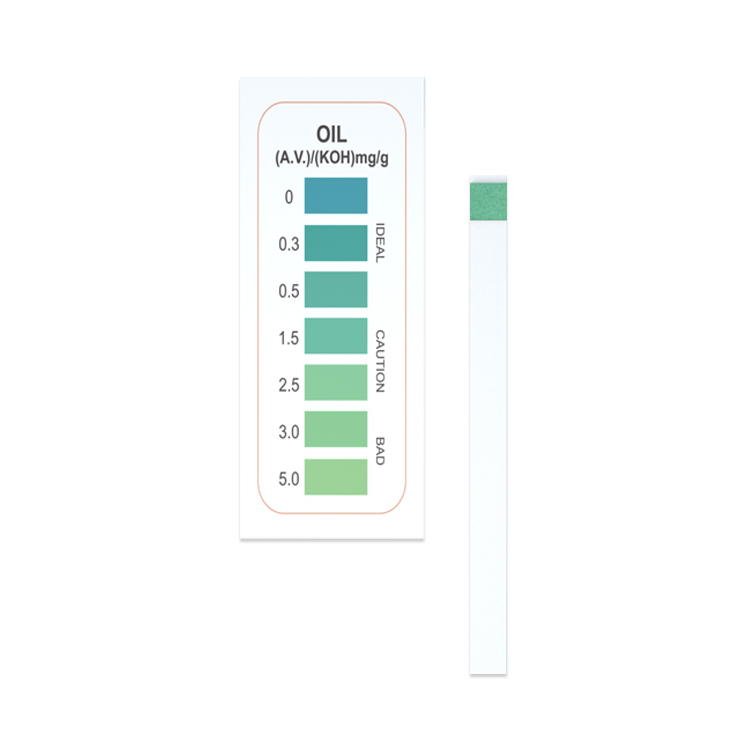

Color -imetric Detection Principle: The color change on the test paper or strip is the key to determining the presence and concentration of oil. The intensity of the color change is proportional to the amount of oil in the sample. Our products are calibrated in such a way that a specific color on the test paper or strip corresponds to a particular oil concentration. For example, a light - colored reaction on the strip may indicate a low concentration of oil, while a dark - colored reaction may suggest a high concentration. Each package of our oil test products comes with a detailed color - comparison chart, which is calibrated through extensive laboratory testing. Users simply compare the color of the test paper or strip after the test with the colors on the chart to determine the oil concentration in the sample.

Detection of Mineral Oils: Mineral oils are widely used in industrial applications. Our oil test paper and strips can detect mineral oils through reactions that target the specific chemical bonds present in these oils. For example, certain reagents can react with the long - chain hydrocarbons in mineral oils to form a colored complex. This reaction is highly specific to mineral oils, allowing for accurate detection even in the presence of other substances.

Vegetable and Animal Oil Detection: In some applications, such as in the food industry or in environmental monitoring of agricultural runoff, the detection of vegetable and animal oils is important. Our test products use reagents that can distinguish between the fatty acid esters present in vegetable and animal oils and other types of oils. These reagents react with the functional groups in the fatty acid esters, resulting in a characteristic color change that can be used to identify and quantify the presence of these oils.

Broad - Spectrum Detection: Our general - purpose oil test paper is designed to detect a wide range of oils, including mineral oils, vegetable oils, and some synthetic oils. It is suitable for applications where a quick screening for the presence of any oil is required. For example, in environmental field surveys, where water samples from various sources need to be tested for oil contamination, the general - purpose oil test paper can provide a rapid indication of whether oil is present. It can also be used in industrial settings for initial checks on the quality of lubricants or process fluids.

Cost - Effective Solution: This type of oil test paper offers a cost - effective solution for applications that do not require highly specific or precise oil analysis. The manufacturing process of the general - purpose test paper is optimized to keep the cost low without sacrificing the reliability of the test results. This makes it an ideal choice for small - scale industries, educational institutions, or for occasional testing needs.

High - Sensitivity Strips for Trace Oil Detection: In applications where detecting even trace amounts of oil is crucial, such as in the pharmaceutical industry or in ultra - pure water production, our high - sensitivity oil test strips are the preferred choice. These strips are designed with advanced reagents and manufacturing techniques to detect oil concentrations as low as parts per billion (ppb). For example, in the production of injectable medications, the water used must be free from any oil contamination. Our high - sensitivity strips can be used to ensure that the water meets the strict quality standards required for pharmaceutical manufacturing.

Specific Oil - Type Detection Strips: We also offer specialized oil test strips that are designed to detect only specific types of oils. For example, we have strips that are highly specific to diesel oil, which is commonly used in transportation and power generation. These strips can be used in applications such as monitoring diesel spills in fuel storage areas or in testing the quality of diesel - based lubricants. Another example is our strips for detecting silicone oils, which are widely used in the cosmetics and electronics industries. These specific - oil - type detection strips provide a more targeted and accurate testing solution for industries that deal with particular types of oils.

Immediate Results: One of the most significant advantages of our oil test paper and strips is the ability to provide rapid results. Traditional oil testing methods often involve sending samples to a laboratory, where they may undergo complex and time - consuming analyses such as gas chromatography or mass spectrometry. These laboratory - based methods can take hours or even days to produce results. In contrast, our oil test paper and strips can provide results in a matter of minutes. For example, in an emergency response situation, such as an oil spill in a water body, our rapid oil test strips can be used on - site to quickly assess the extent of the contamination. This allows for immediate action to be taken, such as deploying oil - containment booms or initiating cleanup operations.

Time - Saving in Industrial Processes: In industrial settings, time is money. Our rapid oil testing products enable operators to quickly check the quality of lubricants, coolants, or process fluids. This means that any issues related to oil contamination can be identified and addressed promptly, minimizing production downtime. For example, in a manufacturing plant, if an operator suspects that the water - based cutting fluid has been contaminated with oil, they can use our test strips to confirm the suspicion within minutes. If oil is detected, the fluid can be immediately filtered or replaced, preventing any negative impact on the manufacturing process and the quality of the final products.

Stringent Quality Control: We are committed to providing reliable quality oil tests. Our oil test paper and strips are manufactured in a state - of - the - art facility under strict quality control measures. The production process involves multiple checks to ensure that each test paper or strip is consistent in its performance. For example, the reagents used in the test products are sourced from high - quality suppliers and are carefully formulated to ensure accurate and repeatable results. Each batch of test products undergoes rigorous laboratory testing to verify its sensitivity, specificity, and accuracy.

Calibration and Standardization: To further ensure the reliability of our oil test products, we follow strict calibration and standardization procedures. The color - comparison charts provided with our test paper and strips are calibrated using known oil concentrations and international standards. This means that users can trust the results obtained from our products, knowing that they are based on accurate and standardized measurements. In addition, we provide detailed instructions on how to use our products correctly, including information on sample collection, testing procedures, and result interpretation, to minimize any potential errors.

Affordable Testing Solution: Compared to expensive laboratory - based oil testing methods, our oil test paper and strips offer a highly cost - effective alternative. Laboratory tests often require expensive equipment, trained technicians, and the cost of sending samples to the laboratory. In contrast, our test products are relatively inexpensive, especially when considering the cost per test. For example, a small - scale industrial operation may not have the resources to invest in costly laboratory equipment for oil testing. Our oil test paper and strips provide an affordable option for them to regularly monitor the quality of their lubricants and process fluids.

Reduced Waste and Cost Savings: By using our oil test products, industries can also save costs associated with waste disposal and product rework. For example, if an industry can detect oil contamination in its process fluids early using our test strips, it can take corrective actions such as filtering the fluids instead of discarding them. This reduces the amount of waste generated and the associated disposal costs. In addition, by preventing product quality issues due to oil contamination, industries can avoid the cost of reworking or scrapping defective products.

User - Friendly Design: Our oil test paper and strips are designed to be user - friendly. They do not require any specialized training or complex equipment to use. The testing process is simple: users simply dip the test paper or strip into the oil - containing sample, wait for a short period (usually a few seconds to a minute) for the color change to occur, and then compare the color with the provided color - comparison chart. This ease of use makes our test products accessible to a wide range of users, from environmental field workers with minimal laboratory experience to industrial operators on the factory floor.

Portability: Another advantage of our oil test products is their portability. The test paper and strips are small and lightweight, making them easy to carry in a pocket, a field kit, or a toolbox. This allows for on - the - spot testing in various locations. For example, environmental inspectors can carry our oil test strips with them during their inspections of water bodies or industrial facilities. They can quickly test water samples at different sites without having to rely on a fixed laboratory location.

Incoming Water Quality Monitoring: Water treatment plants play a crucial role in ensuring the safety and quality of the water supply. Our oil test paper and strips can be used to monitor the quality of the incoming water, whether it's from rivers, lakes, or groundwater sources. By detecting any oil contamination in the raw water, treatment plants can adjust their treatment processes accordingly. For example, if oil is detected in the incoming water, additional filtration or treatment steps can be added to remove the oil before the water undergoes further treatment processes such as disinfection and purification.

Effluent Water Testing: Water treatment plants are also required to meet strict environmental regulations regarding the quality of the effluent water they discharge. Our oil test strips can be used to test the effluent water to ensure that it does not contain any oil contamination. This helps treatment plants to comply with environmental regulations and to protect the receiving water bodies from pollution. In addition, by regularly testing the effluent water, treatment plants can identify any issues with their treatment processes and take corrective actions to improve the treatment efficiency.

Engine Oil Analysis: In the automotive industry, the quality of engine oil is critical for the performance and longevity of engines. Our oil test strips can be used to perform quick and easy engine oil analysis. For example, car owners can use our test strips to check the condition of their engine oil between regular oil changes. By detecting signs of oil degradation, such as the presence of oxidation products or contaminants, car owners can determine whether it's time to change the oil. In addition, automotive repair shops can use our test strips to diagnose engine problems related to oil quality. For example, if a car is experiencing engine knocking or reduced power, the repair shop can use our test strips to check if the engine oil is contaminated or has lost its lubricating properties.

Transmission and Hydraulic Fluid Testing: The automotive industry also uses a variety of other oils, such as transmission fluids and hydraulic fluids. Our oil test paper and strips can be used to test the quality of these fluids. For example, in a transmission system, the transmission fluid needs to maintain its proper viscosity and lubricating properties. Our test strips can detect any changes in the fluid, such as the presence of metal particles or the breakdown of the fluid due to heat or contamination. By regularly testing the transmission and hydraulic fluids, automotive manufacturers and repair shops can ensure the smooth operation of these systems and prevent costly repairs.

Shipboard Machinery Lubrication: Ships rely on a variety of machinery, such as engines, generators, and pumps, which require proper lubrication. Our oil test products can be used to monitor the quality of the lubricating oils used in these machines. For example, in a ship's engine room, the engine oil and the lubricating oils for other machinery need to be regularly tested to ensure their performance. Our test strips can detect any contamination, such as water or fuel dilution, in the oils. By maintaining the quality of the lubricating oils, ship operators can prevent machinery breakdowns at sea, which can be extremely costly and dangerous.

Ballast Water Treatment: Ballast water is used in ships to maintain stability. However, ballast water can contain oil and other contaminants, and its discharge into the ocean must comply with strict international regulations. Our oil test paper and strips can be used to test the ballast water for oil contamination before it is discharged. This helps ship operators to ensure compliance with environmental regulations and to protect the marine environment. In addition, by testing the ballast water, ship operators can also identify any issues with their ballast water treatment systems and take corrective actions to improve the treatment efficiency.

Temperature and Humidity Control: To ensure the accuracy and reliability of our oil test paper and strips, proper storage conditions are essential. The test products should be stored in a cool, dry place away from direct sunlight and heat sources. High temperatures can cause the reagents on the test paper and strips to degrade, reducing their sensitivity and accuracy. In addition, high humidity can also affect the performance of the test products by causing the reagents to absorb moisture, which can lead to false results. The ideal storage temperature for our oil test products is between 2 - 30°C, and the relative humidity should be kept below 60%.

Protection from Chemicals and Light: Our oil test products should also be stored away from chemicals and solvents that could react with the reagents on the test paper and strips. In addition, exposure to light, especially ultraviolet (UV) light, can also cause the reagents to degrade. Therefore, the test products should be stored in their original packaging, which is designed to protect them from light and chemical exposure. Some of our packaging may also include desiccant packets to absorb any moisture and keep the test products in optimal condition.

Expiration Date and Quality Assurance: Our oil test paper and strips have a specified shelf - life, which is printed on the packaging. Under proper storage conditions, our test products can maintain their accuracy and reliability for up to two years from the date of manufacture. However, it's important to note that the shelf - life may be reduced if the test products are stored in sub - optimal conditions.

Factory. We speicalize in producing water test strips for years....more

-

Download

- Category.pdf